Webinar Recap: Front-End Loading for Control System Migration

Blog

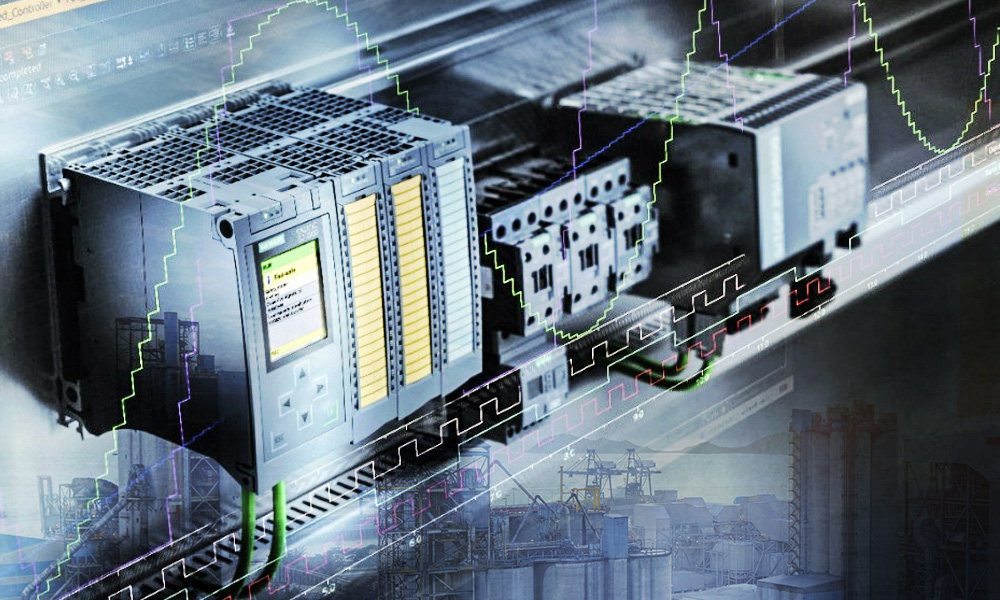

Programming PLCs: Keep the documentation clear and simple

Poor programmable logic controller documentation and housekeeping can lead to unnecessary troubleshooting and downtime. Keep it simple in order to avoid the possible risks and confusion. […]

Power fail-safe state: After the power outage

Identifying a power outage – small or large – is only a fraction of the battle for your equipment. Every time you order a valve or configure […]

DCS migration: Batch or S88 style application?

Deciding between a dedicated batch application and building an S88 style application really comes down to the level of sophistication required to make the system user-friendly and […]