Manufacturing execution system (MES) solutions require a great deal of planning and testing to be successful. Everyone invloved must be on the same page. Most of […]

Blog

Principles for more Effective Automation

Programming is a big portion of process control and following principles such as customer collaboration, responding to changes, and emphasizing individuals and interactions can help a […]

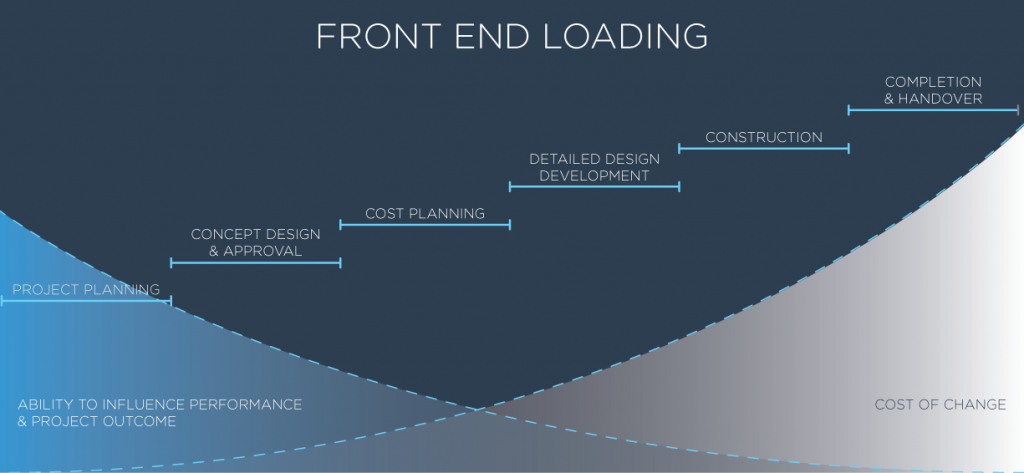

Using FEED for a Successful Batch Implementation

Batch implementation projects are much more likely to be successful when a thorough front end engineering design (FEED) is performed and if several questions are addressed […]

Clear Communication is Key During Projects

Clear communication during a project allows everyone to understand what the goals are and how to overcome potential problems and cab vital in many unexpected ways. […]