New ideas for quality management: Part 1

Manufacturing quality tests in the lab can take time, causing a delay in production. Consider rapid testing with operators to deliver prompt feedback and make necessary adjustments sooner.

OK – that title sounds a little grandiose, like I’ve come up with some brilliant new ideas that no one has ever thought of before. These ideas aren’t necessarily new (or even that brilliant); they’re really more like practical common sense. But, they can have a huge impact on manufacturing quality management and can really make things on the shop floor a whole lot better when it comes to managing quality.

What I’m talking about here is the way that manufacturing quality tests and checks are performed, and the way that the results of those tests are then fed back into the manufacturing processes.

Let me start with some compare and contrast ideas to get this discussion going.

For lots of companies, the lab controls the testing process. They typically have some type of lab and samples are taken from the shop floor and then the lab runs the tests and eventually provides the test results back to the shop floor. The whole process is controlled totally by the lab.

Consider an idea that turns the testing process on its head and puts the operator in charge of quality management. The reasoning for this is simple: The operator is in charge of making the product; the operator is closest to the manufacturing process and really knows what’s going on. Hence, the operator, and not the lab, should be in charge of the quality tests. After all, it’s the operator that needs the information, and it’s the operator that’s going to make the changes in the process based on the information.

With the lab in charge, test results are often very slow. It just seems to take a lot of time for the samples to be taken, processed in the lab, and then delivering the results to the shop floor. In some cases this processes takes a lot of time.

The new idea is to completely change this paradigm and have rapid testing. Get the tests performed quickly, and get the results back as soon as possible. Delay is time, and time is money.

So, with the lab, because of the length of time to get the test results back, there’s a long delay in getting feedback to the manufacturing processes. If something needs to be adjusted, it’s a long time before those adjustments are made, and it’s possible that a product isn’t being manufactured to certain specifications because of the delay.

With the new idea of rapid testing, you can get prompt feedback to the manufacturing processes, so that if things need to be changed you can make the adjustments sooner rather than later.

So, you should be seeing part of the picture here. With the old paradigm, testing takes a long time, getting feedback takes a long time, and the lab controls everything. With the new paradigm we put the operator in control so the lab works for the operator, not the other way around. We then get fast test results and get the feedback to the manufacturing process quickly so that the proper adjustments can be made.

That’s a pretty good start to understanding these new ideas about manufacturing quality. We’ll keep this discussion going next time. Until then, good luck and have fun!

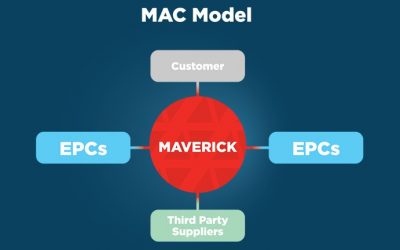

This post was written by John Clemons. John is the Director of Manufacturing IT at MAVERICK Technologies, a leading automation solutions provider offering industrial automation, strategic manufacturing, and enterprise integration services for the process industries. MAVERICK delivers expertise and consulting in a wide variety of areas including industrial automation controls, distributed control systems, manufacturing execution systems, operational strategy, business process optimization and more.