ABB Automation 800xA Control System Services

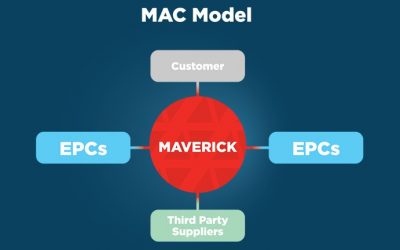

MAVERICK Technologies has the trained professionals to satisfy all of your ABB 800xA system needs. Our engineers have project experience with batch control, continuous control, discrete manufacturing and SIS applications utilizing industrial IT. MAVERICK specializes in 800xA system architecture design, system configuration, system maintenance and upgrades as well as migration planning and execution from virtually any DCS or PLC platform. Our device and 3rd party interface experience includes ethernet/IP, Modbus, ModbusTCP, PROFINET, PROFIBUS, OPC, TRIO, HART and Foundation Fieldbus. We can help enhance and maintain your control system through expertise with asset management, information management history and reporting as well as system diagnostics and server and client virtualization. Our engineers are well versed and trained in OperateIT, Control Builder M and the PG2 and VB6 process graphics editors. Whether you are planning an expansion of an existing system or a migration from a legacy ABB or alternate DCS platform, MAVERICK Technologies has the industry experience and technical capabilities to handle your ABB 800xA system requirements.

The ABB 800xA system uses aspect object technology to create a unified platform base for process control, production management, logic and sequence control, instrumentation and asset management. The 800xA automation system is widely used in the oil & gas, chemical, and pulp & paper industries. It integrates seamlessly with isolated DCS systems.

Read more about our industrial automation services to learn how we can help improve your manufacturing process using ABB Automation systems.