What Is the Cost of Not Automating with State-Based Control?

Everyone in industry is looking to utilize the latest technological advances for a competitive advantage. State-based control gives you that advantage. To better understand why, we must first ask, “What is the cost of not automating with state-based control?” The answer requires a quick peek through history to look at the evolution of automation – and perhaps even more importantly, to look specifically at information technologies.

Evolving System Architectures

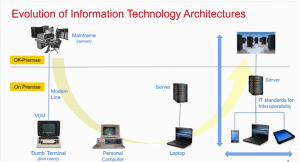

We can see dramatic change from the 1980s until now – from centralized systems to desktops and laptops to today’s environment where we see a variety of smart interconnected devices (see figure 1). Intelligent devices that communicate with each other has taken the IT industry an order of magnitude beyond where it once started. A similar dramatic change can and should be done in how we approach industrial automation systems and processes.

Figure 1. Evolution of Information Technology Architectures

As technologies evolve, the way we use them also evolves. In the 1950s, pneumatic controls allowed for simple loop-based control. In the 1970s, electronic controls opened the door for supervisory controls; hence, the birth of the distributed control system (DCS) and a competing line that handled logical devices – the programmable logic controller (PLC). In the 1990s, these two systems began to merge to the point where they are now more alike than different.

Technological and Hidden Advantages

State-based control can meet the demand for coordinating loops and logic by building in the operating procedure and bringing intelligence to the devices. State-based control can move your system forward to take maximum advantage of today’s technology, similar to the interactive IT smart device model. For instance, it can:

- handle sequencing and supply logic like a PLC

- manage advanced regulatory controls by enabling and disabling various control modes in complex controller scheme

- interact with modeling controls

BUT this is only the beginning! The exciting part is state-based control can do a whole lot more:

- Alarms can become smart, so that they are only active when they are meaningful. There is no reason to have a low-level alarm when you know a vessel is supposed to be empty or a high-pressure alarm when a vacuum pump is supposed to be off.

- Pumps can be easily programmed to automatically come on when their partner goes off and a pump is needed.

- Valve line ups for startup and shutdown can be done automatically.

- Equipment, units and devices become intelligent. They can communicate to each other when it is appropriate and take action accordingly. When a feed system goes offline, downstream equipment can automatically go into recirculation or recycle. Same for a downstream stoppage; by knowing the state of downstream equipment, units can automatically move to a condition that allows them to idle while issues are resolved.

By knowing the ‘state’ of the process, your devices can become smart, knowing what to do whenever the process moves into each state. This also makes the process more operable. Because the operating procedure is essentially built into the automation, it makes it easier for operations. We might make fun of the 1960s animated sitcom character George Jetson having the simple task of ‘pushing the button,’ but in a very real way, the simpler we make the interactions of the operator with the process, the better an operator can manage it.

Some processes may not shut down for years. During that time, the operators have gotten out of practice handling shutdown and startup, and many have moved on since the last time it was done. By building the procedure into the automation, we not only make it easier to follow, but we also make it harder to accidently deviate. This is important as more time and money is lost during the shutdown and startup of an operation than at any other time. We can also add in the safety factor as state-based control has proven to greatly improve safety. Not only during startup and shutdown, but also during normal operations when process upsets occur.

Perhaps the most hidden advantages of state-based control are in asset utilization and reliability. By ‘quieting’ a plant using smart alarms and by making devices intelligent, we can see asset utilization losses due to process upsets significantly reduced. It also helps to reduce fouling. For example, a process unit that had an annual outage for cleaning with a semi-annual pit stop to clean the equipment that fouls quickest can see that time double to a bi-annual outage with an annual pit stop. We can also see asset utilization improve from 85% to 95% simply because we can resolve issues quicker.

State-based control can reduce the number of standing alarms and the alarm frequency dramatically. Additionally, the process runs more quietly allowing operations to focus on real problems and not have to wade through a lot of information to figure out what is important. While operators have reaction time, need breaks and can easily be distracted, the control system acts immediately, is always active and watching.

State-based control greatly enhances the capabilities of operators and allows them to make better informed decisions when they need to. State-based control integrates programming logic with all the advanced forms of automation to make your plant run smarter, more efficiently, more reliably and more safely. The devices become ‘smart’ allowing them to know what to do given the process conditions.

As everyone turns a competitive eye toward leveraging the latest technological advances, consider how state-based control mirrors today’s IT model by building intelligence into individual devices and then coordinating them using states. In this way, significant cost reductions are quickly appreciated in operability, safety and asset management. As you move your systems forward to take maximum advantage of today’s technology, can you really afford not to use state-based control?