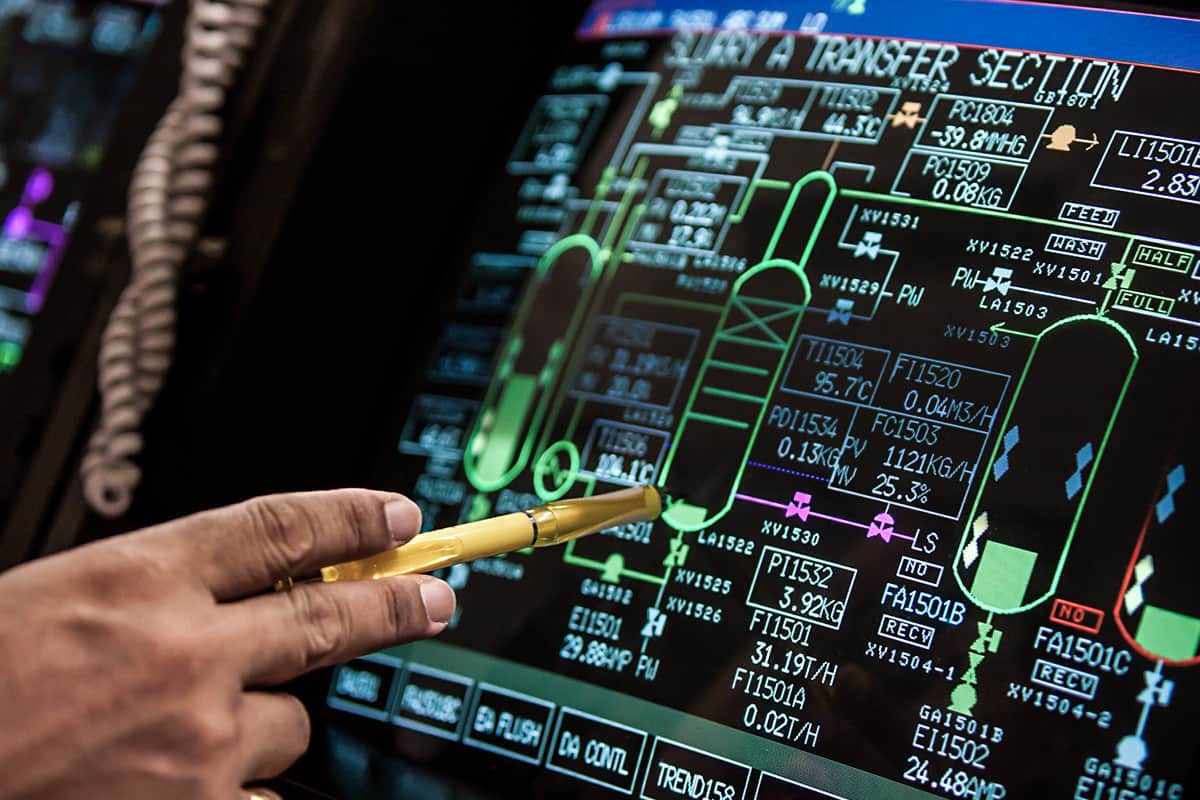

Industrial Automation

Process Automation Services and Solutions

As a platform-independent automation solutions provider, MAVERICK Technologies makes recommendations without bias for technology and supports every phase of your projects — from initial control platform assessment to startup and commissioning to ongoing maintenance.

We needed help to perform a planned shutdown, and MAVERICK stepped in with skilled resources.

— Satisfied Customer, Pulp and Paper Industry

Specific industrial automation services include:

Automation Solutions

Leverage your existing assets to increase output, improve quality and efficiency, ensure safety and comply with regulations.

Advanced Process Control

Reduce process instability and operate closer to constraints by capturing your intellectual property within the process itself.

Field Services

Dispatch experts quickly to handle anything from installation to construction management, in any geographic region.

Large-Scale Project Execution

Tap into our resources and drive your large-scale project to success.

Industrial Automation Consulting Expertise

We have experience with a wide variety of industries and technology platforms. Our proven execution methodology guides our process to ensure safe, cost-effective and timely project completion.