Automation Projects: Why so Difficult?

Today’s process automation projects present unique challenges for project managers and their teams, who have found them more difficult to execute than other types of projects. Why is that? Let’s review some key factors based on my own years of experience as a project manager and conversations with my peers.

Component challenges

Faced with a highly fragmented process automation industry, project teams must work with numerous suppliers who each control a small portion of the market. A typical automation project contains thousands of individual components. The project team is responsible for making sure all those components work together. The resulting designs are highly engineered and customized for each application.

Another challenge is the automation equipment itself, which contains rapidly changing computer, software and electronics technology. Unlike other disciplines, automation knowledge becomes outdated every few years as the underlying technology advances making it a challenge to keep technical resources knowledgeable on the latest best practices.

Definition challenges

Unlike other types of projects, automation scope evolves throughout the project’s life cycle, even through startup. Expecting to completely define the scope up front with no changes is not realistic. This is where project organizations focused on civil- and mechanical-type projects often stumble.

Design inputs for automation come in piecemeal throughout the project as the other disciplines perform their detailed engineering. Some operations requirements are not completely defined until the operators have a chance to put their hands on the system during testing and commissioning.

Schedule challenges

Automation requirements are not revealed until other disciplines execute their own engineering tasks. For example, before instrumentation and control valves can be specified, process engineering needs to define the process conditions and control requirements and mechanical engineering needs to define line sizes, materials of construction, and any physical installation constraints.

Automation is always on the critical path for completion. Loop checks and commissioning can only be done after construction is completed to keep from violating the integrity of the tested system. And when the overall project is late, the pressure is put on the automation effort to make up for lost time.

Human challenges

While there has been excellent human factors science applied to automation in recent years, there are still personal preferences to be accounted for. Because the automation system is THE interface between the plant and the operator, it seems everyone has an opinion about how it should look and feel. These personal preferences are difficult to completely define but need to be accommodated or respectfully rebuked to make the system fully effective yet achieve operator buy-in.

There is also a creative element to contend with. Modern automation systems allow significant flexibility in how various functions are implemented. While this flexibility enables the automation system to be customized to optimally control the process, it also makes requirements difficult to define and enforce.

A worthy endeavor

Managing process automation projects is a difficult, but worthy endeavor. For me, the challenges those projects present make for a stimulating and rewarding career. Embrace the challenge and enjoy the adventure!

ABOUT THE AUTHOR

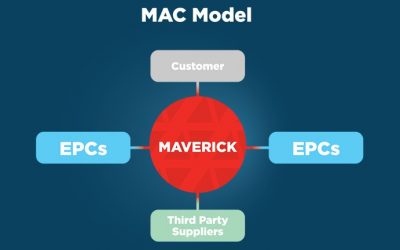

Lee Swindler (lee.swindler@mavtechglobal.com) is a Program Manager with MAVERICK Technologies. Lee has 30 years of automation industry experience, including 21 years in manufacturing and 9 years on the engineering services side. He holds a Project Management Professional (PMP) certification along with being a TÜV Certified Functional Safety Engineer (FSEng). Lee has a B.S.E.E degree from the South Dakota School of Mines and Technology.